DRUCKLUFT-KOMPRESSOREN

Air compressors

How does a compressor work?

Mostly, compressors in the tradesman's sector are devices with piston compression. This principle is easy to explain. A motor drives the piston, which moves within the cylinder. This causes the piston to suck in outside air and compresses it in the next step. The compressed air is now stored in a boiler. If required, the valve on the boiler now allows the previously compressed air to be released precisely. Nearly all compressors have an automatic motor shut-off when the maximum air pressure is reached. A safety valve prevents the pressure in the boiler from becoming too high. The motor is reactivated as soon as the pressure in the boiler falls below a certain level.

Which air compressor for which field of application?

Depending on the requirements and the area of application, different compressors are also required. Therefore, you should always pay attention to this before the purchase is made. Many will only need a compressor for occasional checking and topping up of the tyre pressure, while others will need a compressor for professional continuous use.

For occasional use, small compressors without an air reservoir are often sufficient. For the use of pneumatic tools and for painting, however, you should consider to purchase a larger unit. Normally, air compressors with a capacity of 20-50 litres are the appropriate size in this case.

How much pressure does a compressor need?

The maximum achievable air pressure is given in bar and, in addition to the capacity of the boiler, is decisive for the possible applications with the compressor. A basic reminder is certainly helpful here. The harder the work to be done, the higher the required air pressure. However, the required air pressure is in any case always indicated on the compressed air tool. So, you are sure to find the right tool for individual needs.

Maintenance of an air compressor

Condensate is produced during the production of compressed air. It is polluted by the particles contained in the drawn-in air and should therefore be regularly drained. The compressor will enjoy a longer service life and operation runs smoothly. The condensate may only be disposed of in special waste, as it contains pollutants that must not be found in household waste. All filters in the compressor should also be cleaned regularly, or replaced if necessary.

Important: Always open the valve carefully to avoid splashing!

WALTER Druckluft KOMPRESSOREN UND DAS PASSENDE ZUBEHÖR-SET

This set consists of following components:

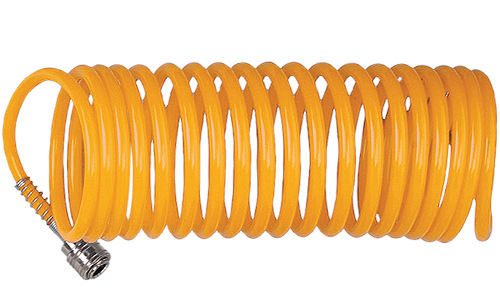

The compressed air spiral hose with a total length of five metres ensures that flexible working is possible with ease.

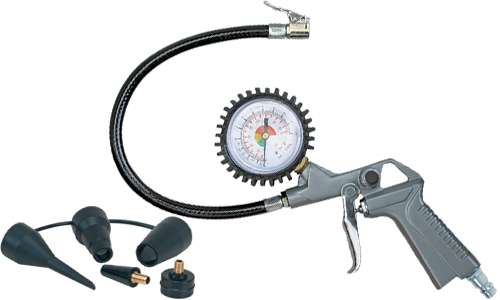

The tire filler has a pressure gauge which makes checking the air pressure in tires more than easy. Included here is the practical universal valve, as well as three additional adapters, which can be attached to the clamping valve with the also included intermediate piece. This makes the tire inflator versatile and an absolute must-have.

The blow-out pistol is perfectly suited for all blow-out work. Dust and dirt is thus declared the battle.

The spray gun with suction cup can be used in the automotive, agricultural and private sectors. The intensity of the atomisation and the amount of material can be varied at the spray nozzle and in addition, the air consumption can be regulated by pulling the trigger more or less strongly. The suction cup has a capacity of one litre and enables a working experience that is not interrupted by a constantly required refilling.

In combination with the aluminium suction cup, the paint spray gun offers the ideal set for applying paint. When working with it, we recommend a distance of 15-25 cm, which ensures an optimal result. With the regulation screw you can adjust the type of paint jet and with the paint quantity regulation screw you can adjust the amount of paint used.

Very good (4.66 / 5.00)

Very good (4.66 / 5.00)